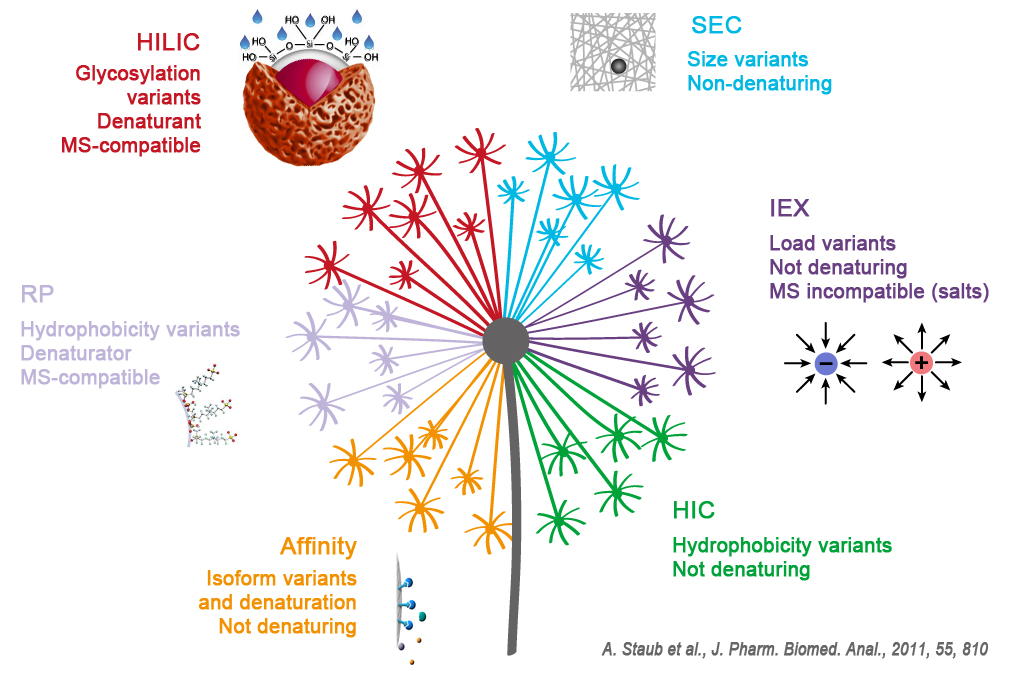

HIC is also known as “Salting outâ€. The separation is done following the hydrophobicity of the protein. In this method, proteins containing both hydrophilic and hydrophobic regions are applied to an HIC column under high salt buffer conditions Thanks to the salt the hydrophobic regions of the proteins are exposed.

The HIC depends on salt concentration of the mobile phase (eluent), pH, temperature & organic solvents use (if ever some are used).

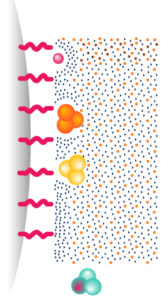

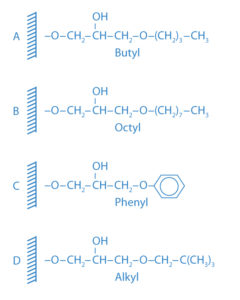

The hydrophobic ligand on the resin are more often Ether, Butyl or Phenyl groups.

Â

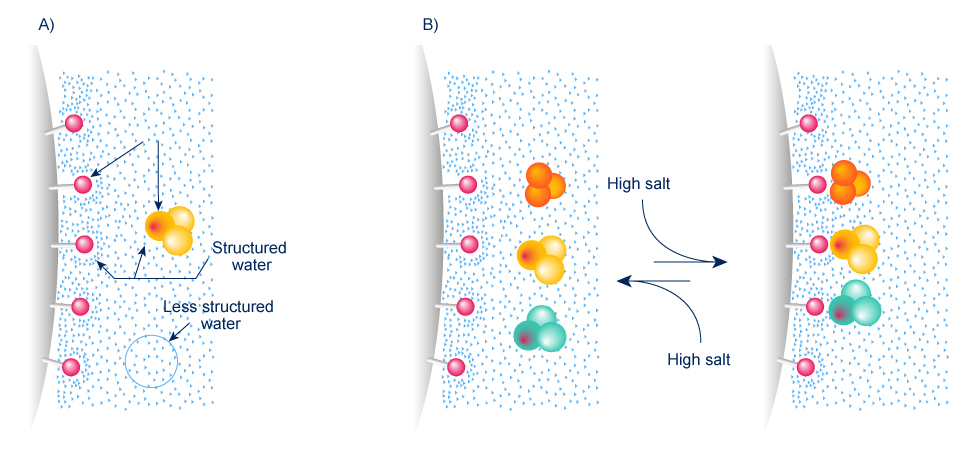

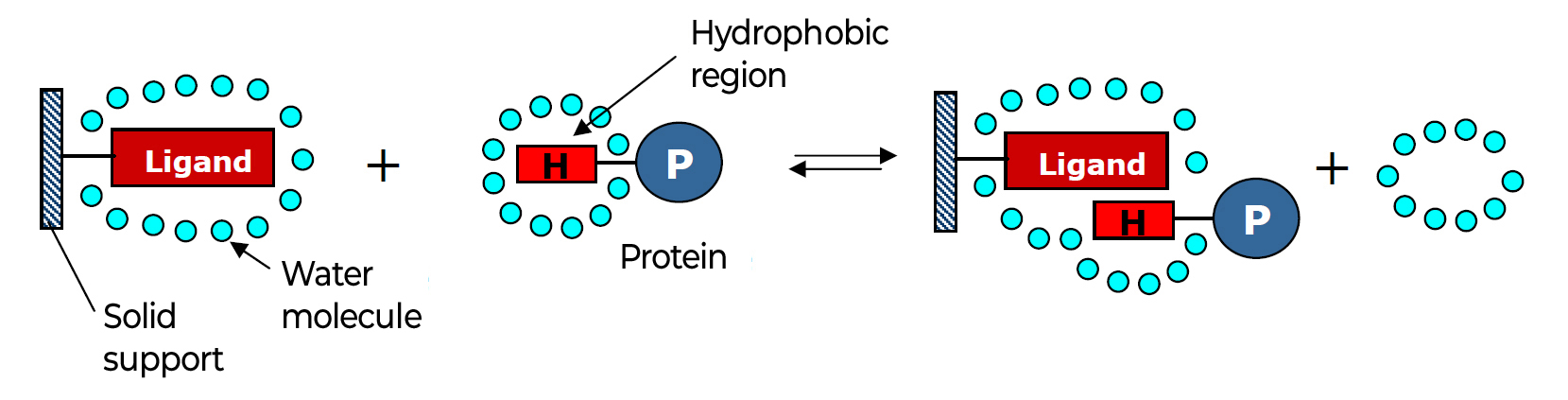

A) In contact with hydrophobic groups water is perfectly structured: Hydrophobic group can’t linked together.

B) Salt destroy the structure of the water: hydrophobic group linked together

Â

|

Very useful for analysis & purification of:

|

|

Advantages

Disadvantage

|

Â

Separation principle

- Proteins get hydrophobic & hydrophilic region.

- In aqueous solution (low salt concentration), these regions are surounded by a thin layer of arranged water molecules.

- At high salt concentration the protein solvatation ratio is decreased (number of water molecules links to salt molecules) so the hydrophobic regions are exposed and they can be adsorbed on an hydrophobic resin.

Â

Separation feature

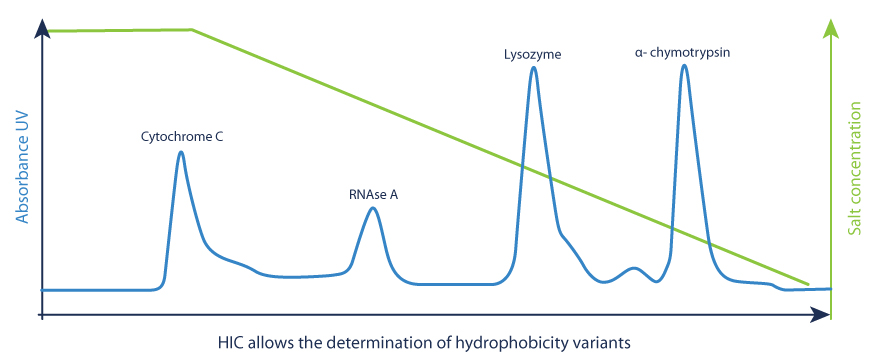

- The model proteins are eluted in order of increasing hydrophobicity, but resolving power of HIC is extremely limited

- The amount of salt required to perform HIC separation is incredibly large (~ 2 M ammonium sulfate)

- The stationary phase should not be too much hydrophobic (C4 bonding with very low ligand density)

Â

Factors of influence on Hydrophobic Interaction Chromatography

1. Ligand type & substitution degrees

|

|

Â

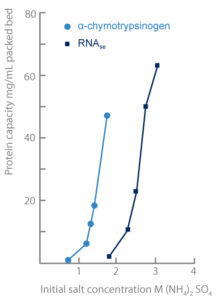

2. Concentration & salts type

Â

|

|

| Binding capacity on a phenyl column vs initial salt concentration | Hofmeister serie & effect on the precipitation

<——————————————-Precipitation increase (“salting outâ€) Anions : PO43- > SO42- > CH3COO– > Cl– > Br–, NO3– > ClO4–  cf: Arch. Biochem. Biophys. 183 (1977) 200–215, Melander, W.,Horvath, C.Separation & Purification Methods 9 (1980) 267–370, Srinivasan, R., Ruckenstein, E. |

Â

3.pH

pH increase: Hydrophobic interactions decrease. Probably because more negative sites are created. The protein is more hydrophilic.

pH decrease: Hyydrophobic interactions increase. Probably due to a protein conformation changing. The protein is more hydrophobic.

Â

4. Temperature

Generally hydrophobic interactions increase when temperature increase due to the entropic effect & Van der Waals strength.

However protein can be denaturated when the temperature increases. Its solubility in solution is modified & lead to its precipitation.

Â

Â

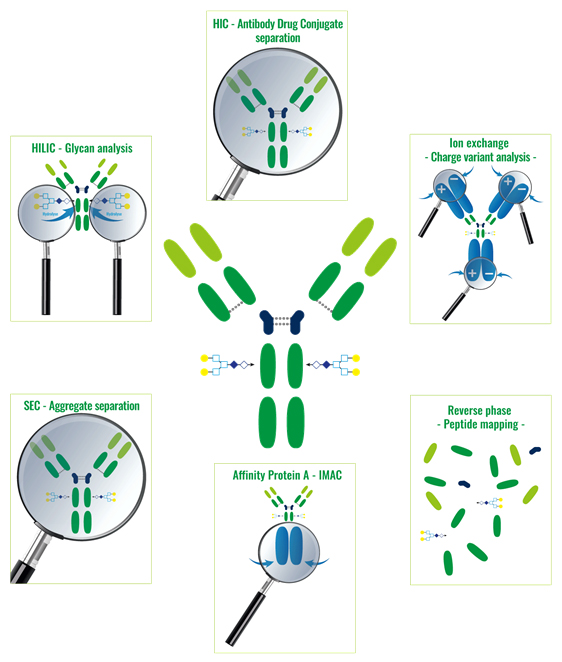

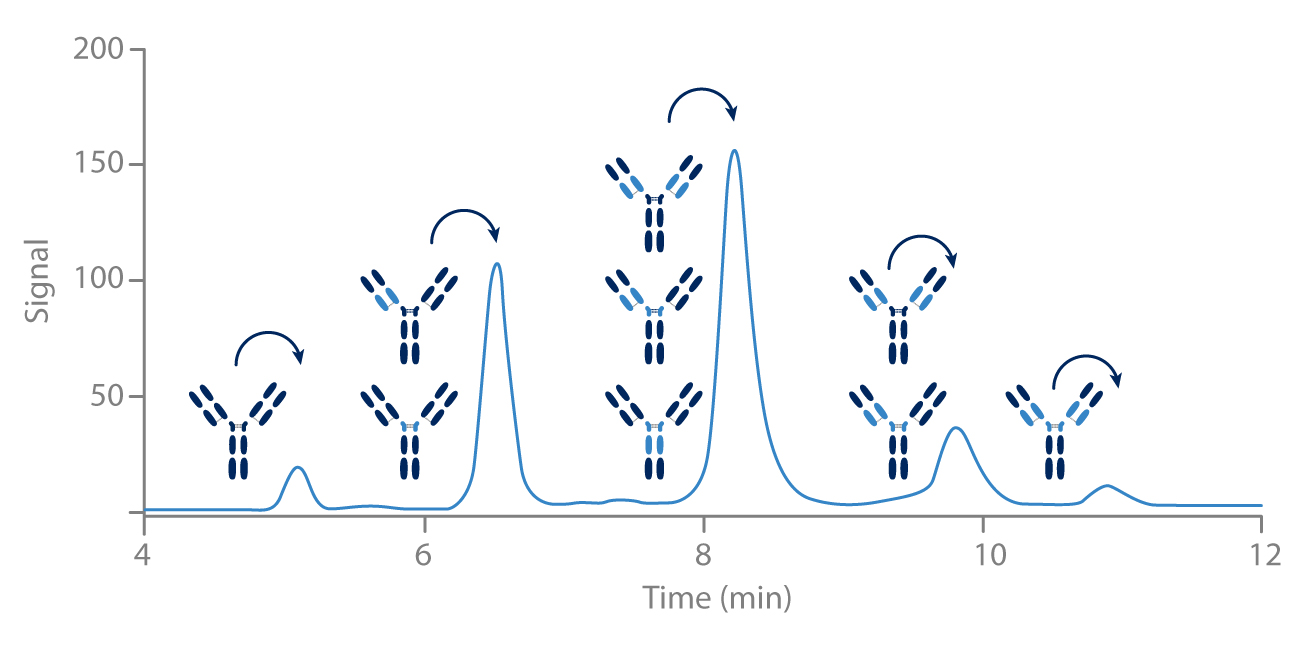

HIC for ADCs

HIC is particularly well suited for ADCs purifications.

ADCs are complexed molecules composed of a mAb linked via a stable linker with labile bonds, to a biologically active cytotoxic drug. The conjugation can be done on:

- Cystein (e.g. Brentuximab Vedotin)

- Lysine (e.g. Trastuzumab Emtansin)

More than 50 ADCs are currently in clinical trials.

The separation is based on the number of conjugated drugs.

A. Beck et al., Disc. Medicine, 2010, 10, 329-339

Â

Know more:

- Contact us:

- Visit our website: www.interchim.com

- Our previous articles on protein purification techniques:

– Guide: Analysis and purification technics of biologicals molecules

– Analysis & purification of proteins: all about Ion Exchange Chromatography (IEX)

– Protein purification technics : Affinity

– Analysis & purification of proteins: SEC (Size Exclusion Chromatography), the separation of molecules according to their sizes

I. Introduction

Cationic fixing agent is polyelectrolyte, consists of a series of organic synthesis with low molecular weight and strong cationic, which is generally 100% cationic. Product character is aqueous solution.

II. Performance Indicators:

1. Appearance: colorless to pale yellow viscous liquid

2. Solid content: ≥ 50%

3. PH: 2 ~ 6

4. Viscosity: 50 ~ 200 mpa.s

III. Application Field

Used in paper pulp as a cationic fixing agent. Usually the slurry contains colloidal particles consisted of fiber materials, additives and water, which are with anionic charge and interfere the papermaking process, so it is also known as anionic trash; the interference is mainly in the following aspects:

1. Influence wet chemical additives` normal function, especially for cationic retention and drainage aids, sizing agent; or cause to increase the amount of wet chemical additives;

2. Deposits in the paper machine system; interfere the efficient papermaking process.

3. COD discharge of sewage systems, increasing the load on the sewage treatment plant. Recommended for use in mechanical pulp, chemi-mechanical pulp, and secondary fiber pulp slurry and coating waste stuff. Anionic trash neutralized by fixing agent can be bonded to the fibers so as to be taken away by paper sheets.

IV. Methods of Application

Adding methods: excellent water-solubility; can spread out in water instantly. Dosing pump is generally used to drive it into a static mixer or a mixing pump , mixed with water, diluted to about 0.2% of the dissolved solution, and then into the slurry system.

Adding point: the general adding point is in the front of flow system, that is, before the machine chest or fan pump; or add in the pulp plant. Which is taken into consideration for the reaction time of the cationic fixing agent polymer molecules and garbage, also need to time and space for other wet end additives. According to the slurry source, sometimes you need to select two or more points to add. When the slurry contains a source of coated broke, generally requires additional anionic trash fixative in the transport of the paper sheet.

Adding dosage: anionic trash content in the slurry is usually gauged by the cationic charge contents measured by PCD (particle charge analyzer) in the slurry. The measure will directly show the dosage tips, but the real dosage depends on the practical application. For general slurry, the recommend amount is in the range of 0.3kg ~1.8kg/t dry pulp.

V. Safe Operation

1. Cationic fixing agent is a water-soluble polymer, dissolved in water in a highly slippery state and avoid to spill on the floor. If spill, shall timely absorb with sand, sawdust.

2. Wear gloves, wear overalls to operate.

VI. Storage

The product should be kept sealed, stored in cool, dry, ventilated places, and appropriate temperature should be 10-30 ℃.

VII. Package

200 kg plastic drums or 1000 kg PE IBC drum.

Fixing Agent,Fixer,Anionic Trash Catcher,Charge Neutralizer

Shandong Tiancheng Chemical Co., Ltd. , https://www.tianchengchemical.com